Cratering

Also known as: Foaming

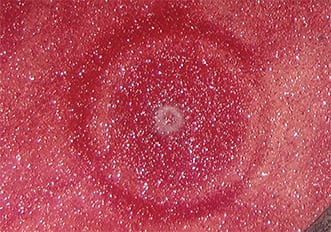

Circular recesses with a diameter from 0,5 to 3 mm. The problem may range in appearance from a very flat recess in the topcoat to a deep fault which extends back to the substrate.

If incorrectly repaired, the original craters may reappear as a more flat recess.

Craters are caused by low surface tension contamination that is on the substrate being painted, is in the paint, or falls on the paint. This produces a surface tension gradient that causes flow away from the low surface tension area, resulting in a circular low spot

Circular recesses with a diameter from 0,5 to 3 mm. The problem may range in appearance from a very flat recess in the topcoat to a deep fault which extends back to the substrate.

If incorrectly repaired, the original craters may reappear as a more flat recess.

it is difficult to identify contaminants and their source. Rigorous inspections of paint shops have turned up sources such as poor substrate cleaning, oily overhead chains, smoking ovens, oil in the compressed air, and dirty paint booths, but often there is no obvious cause. If the contaminant can be identified, then there is a good chance that its source also can be found.

Cause

Mainly: Oil, grease, wax and silicon residue. (e.g. polishes containing silicon).

- Marks from clothing, rubber gloves, skin and hair lotions.

- Lubricants from moving parts, release agents from plastic parts, hoses and sealants, inadequate oil and water trap bleeding, dirty ceiling and floor filters.

- Incorrect use of paint additives (Anti-silicon additive), unsuitable thinner/hardener impurities from poor transportation or storage.

- Residues from release agents (on plastic parts) slip additives, solder flux, bitumen and oil from insulating mats.

- Release agents from new sponges, unsuitable, cleaning agents or abrasives, adhesives from tapes.

- Intake of polluted air from other work areas (polishes, oil sprays, release agents, fine dusts etc) sealant and insulation dusts from the building.

Prevention

Shallow craters often can be polished out, but deep ones require sanding and repainting. Craters vary in size and appearance, even from a given contaminant. The majority of cases that I have encountered in auto plants have involved contaminants falling on the wet coating during or soon after application, but the other possible causes always must be considered.

- many of the causes of cratering in paint finishes, from which it is possible to take precautions to avoid the the contamination.

- In principle, we would recommend that only silicon-free products are used in the vicinity of the paintshop, and substrates are

always cleaned thoroughly.

Remedy

- Avoid excessive rolling or brushing of the paint or using paint that is more than a year old. Apply gloss and satin paints with a short nap roller, and apply an appropriate sealer or primer before using such paint over a porous surface. Problem areas should be sanded before repainting.

- Avoid excessive rolling or brushing.

- Avoid using paint that is more than a year old.

- Prime porous surfaces before applying paint.

- If applying gloss or semi-gloss paints, prime before painting and use a short nap roller.

- Avoid vigorous shaking of the paint can or swirling the brush in the paint.

- Sand problem areas before repainting.